Cyclic Carbodiimide

Introduction and Features

Teijin's new resin additive cyclic carbodiimide is cyclic compound containing carbodiimide bonds. It is a new type of additive that exerts various effects depending to resins and applications, including not only suppression of hydrolysis, which is innate ability of carbodiimide additives, but also improving heat resistance and increasing melt viscosity.

Features

Structure and effects of cyclic carbodiimide

Structure schematic of cyclic carbodiimide

| Resins | Expected effects of cyclic carbodiimide |

|---|---|

| Polyester Polyamide Polyurethane |

|

| Combinations of the resins above |

|

| Thermosetting resins |

|

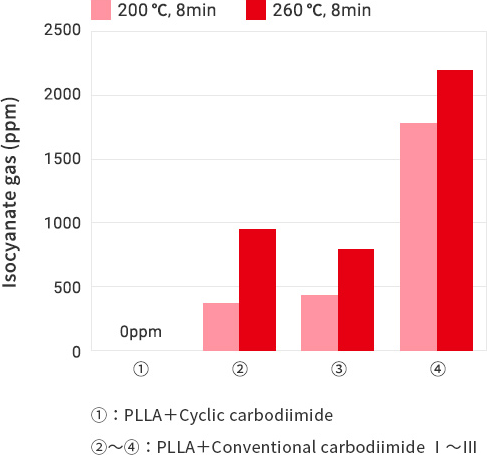

Novel hydrolysis inhibitor without generation of isocyanate gas

The amount of generated isocyanate gas when added to polylactic acid

Cyclic carbodiimide is a hydrolysis inhibitor that does not generate harmful isocyanate gas when mixed with resins thanks to its cyclic structure. It is possible to be manufactured and used safely at manufacturing sites.

Grade Lists

Cyclic carbodiimide is powder type additive for resins. Standard type and fine powder type are available

depending to applications.

Composition and reaction uniformity at kneading to resin or dispersing to solution

can be obtained by making it into fine powder form.

| Type | Grade | Size | |

|---|---|---|---|

| D50 | |||

| Standard powder | TCC-NP | 100~200 µm | Thermoplastic resins (For melted kneading) |

| Fine powder | TCC-FP20M | 3~5 µm | Paints / thermosetting resin (For solution dispersing) |

| TCC-FP10M | 1~2 µm |

Engineering Service

Thermal properties

Cyclic carbodiimide can be mixed with resins even at high temperature range thanks to melting point above 230℃ and a thermal stability above 300℃, due to its unique molecular design.

Thermal properties of cyclic carbodiimide

| Tm (℃) | 1% weight loss temperature (℃) | 5% weight loss temperature (℃) |

|---|---|---|

| 230 | 365 | 397 |

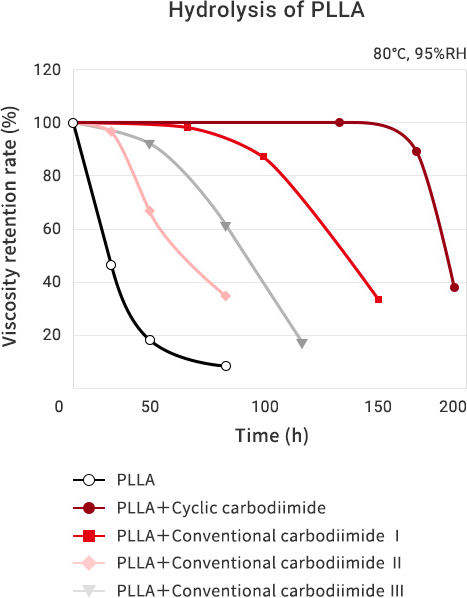

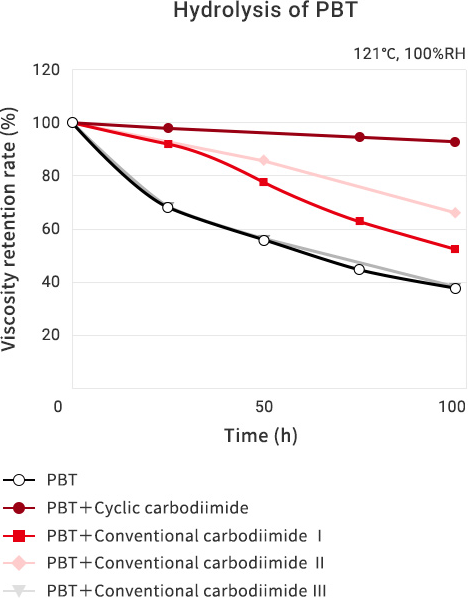

Improvement of hydrolysis resistance of resins

Cyclic carbodiimide can be applied to a wide range of resins such as polyester, polyamide, polyurethane and

polylactic acid without deteriorating the performance of each resin.

In addition, It can impart higher

hydrolysis resistance performance by adding a smaller amount of cyclic carbodiimide than conventional

carbodiimide additives.

Hydrolysis properties when added to polylactic acid (see left graph) and polybutylene terephthalate (see right graph)

Easy to handle

Cyclic carbodiimide is a highly reactive compound that is extremely stable during storage and easy to handle.

■ Equilibrium moisture content measurement(TCC-FP10M)

| Immediately after drying | 1 day later | 7 days later | 30 days later | 180 days later | 240 days later | 366 days later | |

|---|---|---|---|---|---|---|---|

| water content(ppm) | <100 | <100 | <100 | <100 | <100 | <100 | <100 |

【Evaluation method】

After the sample was dried under reduced pressure at 80°C for 24 hours, the sample which was open state was placed in a constant temperature and humidity chamber (adjusted to 24°C and 50%), and the moisture content was measured over time.

【Measurement method】

Heating vaporization/Karl Fischer Coulometric Method

■ Evaluation of hydrolysis resistance of carbodiimide groups

| Carbodiimide group residual rate(mol %) | |||

|---|---|---|---|

| 0 hr | 24 hrs | 48 hrs | |

| TCC-NP | 100.0 | 100.0 | 100.0 |

| Conventional carbodiimideⅠ | 99.7 | 0.0 | 0.0 |

【Evaluation method】

Each sample was placed in a constant temperature and humidity chamber at 85°C and 85% RH, took it out after 24 hours and 48 hours, and analyzed the structure by 1H-NMR.

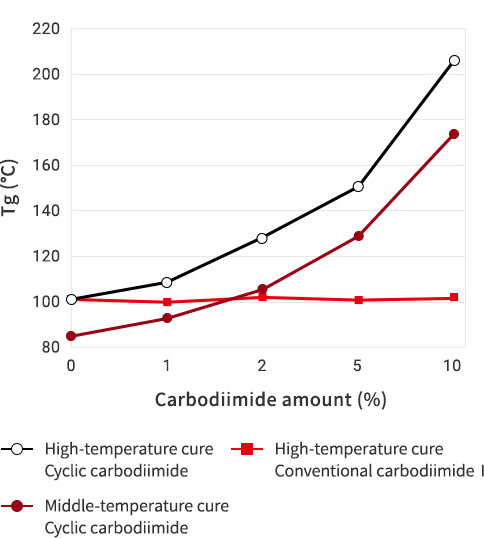

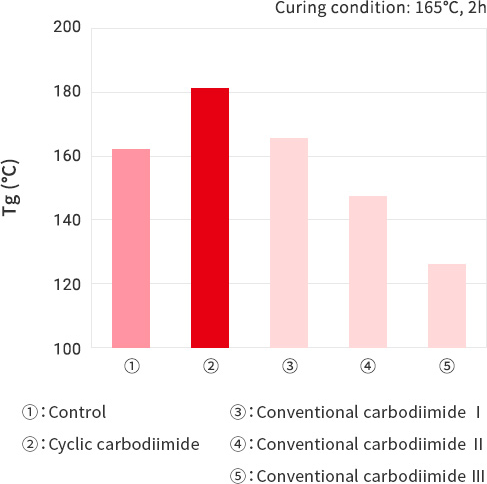

Improvement of heat resistance of thermosetting resin

Cyclic carbodiimide functions as curing aid for thermosetting resins, and it can impart high heat resistance without adversely affecting various physical properties that are traded off in the prior art.

Change in glass transition point (Tg) when added to epoxy resin

- *The values listed above are typical values based on standard test

methods and do not guarantee performance in any particular application.

These contents are subject to change without notice.