Polyethylene Naphthalate (PEN) Resin Teonex®

Introduction and Features

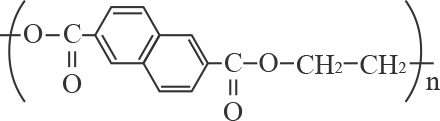

Polyethylene naphthalate (PEN) resin became popular in various fields after U.S. company Amoco Chemicals started commercial production of naphthalenedicarboxylic acid (NDC) , a raw material of PEN, in 1995. In 1964, 31 years before that, Teijin started development of PEN and commercialized as Teonex®. Since then, Teonex® has been popular as a functional material for industrial parts and wrapping materials for food and drugs, and still steadily increasing the area of applications. Teonex® is a crystalline thermoplastic polyester, a polycondensate of NDC as an acid component and ethylene glycol as a glycol component, manufactured in a process similar to that of polyethylene terephthalate (PET), a typical polyester. The property of Teonex® is considered superior to that of PET. Teonex® is crystalline resin, crystallized slowly, making it easier to shape transparent molded products. Teonex® has a superior chemical and scratch resistance compared to polycarbonate (PC) resin, a typical resin used in transparent molded products.

Features

- 1.High transparency.

- 2.+50℃ of thermal resistance compared to PET.

- 3.Higher hydrolysis resistance and longer life than PET.

- 4.Higher chemical resistance than PET and PC.

- 5.Reduces the concern for contamination thanks to low levels of outgassing and adsorption of organic materials.

- 6.Absorbs ultraviolet radiation (up to 383nm) and protects contents inside.

Usage examples for application fields

- Returnable bottles

- Cosmetic containers

- Plateware

- Medical product containers

- Blending materials to improve PET performance (moisture barrier, gas barrier, heat resistance, UV ray absorption, etc.)

- Components that requires transparency, heat resistance, or chemical resistance

Grade Lists

Properties

| Property | Unit | Measurement method | Measurement condition | Teonex® | PET | Panlite® | |

|---|---|---|---|---|---|---|---|

| TN-8050SC | TN-8065S | L-1250Y | |||||

| MVR | m3/10min | ISO 1133 | 300℃, 1.2kgf | 18 | 5 | - | 8 |

| Density | kg/m3 | ISO 1183 | - | 1,330 | 1,330 | 1,330 | 1,200 |

| Tensile modulus | MPa | ISO 527-1 and ISO 527-2 |

1mm/min | 2,200 | 2,200 | 2,300 | 2,400 |

| Tensile yield strength | MPa | 50mm/min | 80 | 80 | 58 | 61 | |

| Tensile yield strain | % | 50mm/min | 7 | 7 | 4 | 6 | |

| Tensile stress at break | MPa | 50mm/min | 38 | 40 | 28 | 75 | |

| Tensile strain at break | % | 50mm/min | 15 | 50 | >200 | >50 | |

| Flexural modulus | MPa | ISO 178 | 2mm/min | 2,250 | 2,200 | 2,500 | 2,300 |

| Flexural strength | MPa | 2mm/min | 99 | 98 | 81 | 91 | |

| Charpy impact strength | kJ/m2 | ISO 179 | Un-notched | 98 | NB | NB | NB |

| Notched | 2.0 | 2.8 | 3.5 | 76 | |||

| Temperature of deflection under load | ℃ | ISO 75-1 and ISO 75-2 |

1.80MPa | 91 | 92 | 65 | 129 |

| 0.45MPa | 105 | 107 | 68 | 142 | |||

| Rockwell hardness | - | ASTM D 785 | M scale | 107 | 107 | 80 | 67 |

- Japan

- Comply with the various notifications of Food Sanitation Act, and comply with the positive list of Japan Hygienic Olefin and Styrene Plastics Association.

- EU

- Grade TN8065S and TN8050SC comply with European Commission Regulation (EU) No 10/2011

Engineering Service

Characteristics

- Crystalline properties

- Optical properties

- Pencil hardness test

- Frictional properties

- Chemical resistance

- Permeability to gases

- Adsorption

- Anti-hydrolysis

- Mold shrinkage

- Flow properties

Design and molding

- Processing molded product