Teijin's Decorative Films

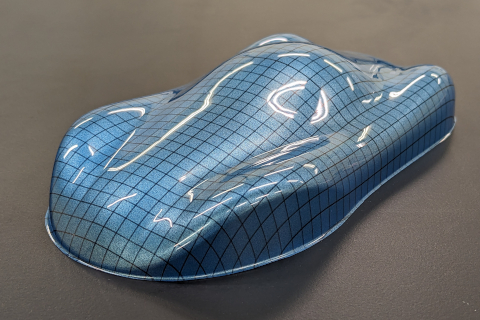

In recent years, there has been a demand for reducing environmental impact through paintless solutions and improving design aesthetics, such as light transmissive indication. As a way to solve this problem, we have adopted insert molding and out-mold molding of decorative films to eliminate the need for painting, improve functionality (scratch resistance, chemical resistance, weather resistance), design (light transmission, 3D shape, seamless), and studies are underway to integrate large parts. In addition, the method of forming electronic circuits on films for the purpose of reducing the number of components is also studied. The Resin and Plastic Processing Business Unit of Teijin continues the development of next-generation decorative PC-based films by utilizing Teijin's unique polymer and compound technologies as base material films that enable such approaches.

For any difficulties in these methods, please contact Teijin.

Teijin's Strength in Decorative Films

1.Applicable parts

Major applications

- Automobile interior parts

- Automobile exterior parts

- Parts for smart appliances

- Housing equipment

- Amusement equipment

2.Services

- Film improvement technology utilizing Teijin's unique polymer and compound technologies

- Proposal of conditions recommended for each type of method

Thermoforming, UV curing, insert molding, and other conditions - Proposal of appropriate injection molding materials

- Prototyping and verification at Chiba Technical Center

- Mold design support with 3D printers

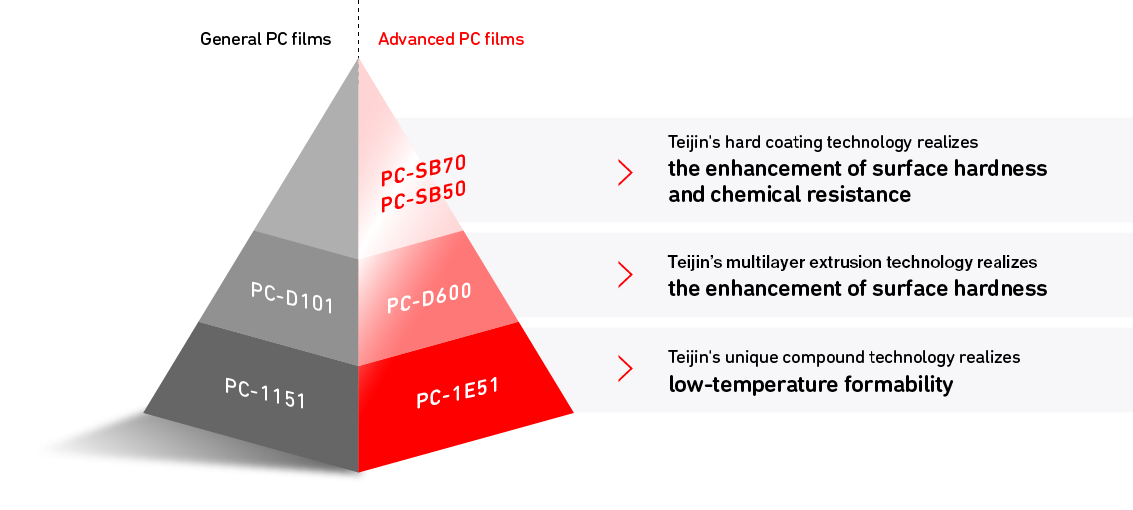

3.Product

- Easy formability and low-temperature formability in the thermoforming process

- Hard coating technologies

Realize surface hardness, abrasion resistance, chemical resistance, weather resistance, and thermoformability - Optical characteristics

Coloring, IR transmission, IR absorption, retardation control, diffusion, light guiding, and other characteristics

Characteristics of Teijin's Decorative Films

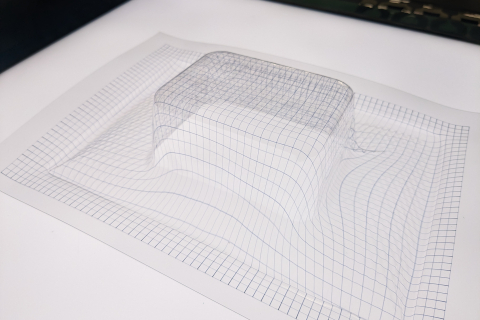

- Even complex and deep-drawn shapes can be thermally formed at lower temperatures than standard PC films.

Characters

| Property | Unit | Test method | Measurement conditions | PC- 1151 (Standard) |

PC-1E51 | PC-D101 | PC-D600 | PC-SB50 | PC-SB70 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Density | g/cm3 | ISO 1183 | - | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | |

| Tensile yield stress | MPa | ISO 527-1 and ISO 527-2 |

50mm/min | 60 | 65 | 60 | 65 | 65 | 60 | |

| Tensile fracture designation distortion | % | 150 | 180 | 5 | 5 | 5 | 5 | |||

| Tensile modulus | MPa | 2,100 | 2,300 | 2,200 | 2,500 | 2,400 | 2,400 | |||

| Total light transmittance | % | ISO 13468 | 0.3mm thick | 90 | 90 | 91 | 91 | 91 | 91 | |

| Haze | % | ISO 14782 | 01 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1*1 | ||

| Color | L | - | ISO 7724-2 |

96.0 | 96.1 | 96.5 | 96.5 | 96.3 | 96.3 | |

| a★ | 0 | 0 | 0 | 0 | 0 | 0 | ||||

| b★ | 0.2 | 0.3 | 0.4 | 0.4 | 0.4 | 0.8 | ||||

| Coefficient of linear expansion | ×10-5/℃ | ISO 11359-2 | - | 7 | 7 | 7 | 7 | 7 | 7 | |

- *1 After forming at 140°C

- * The values in the above table are measured, not guaranteed values.

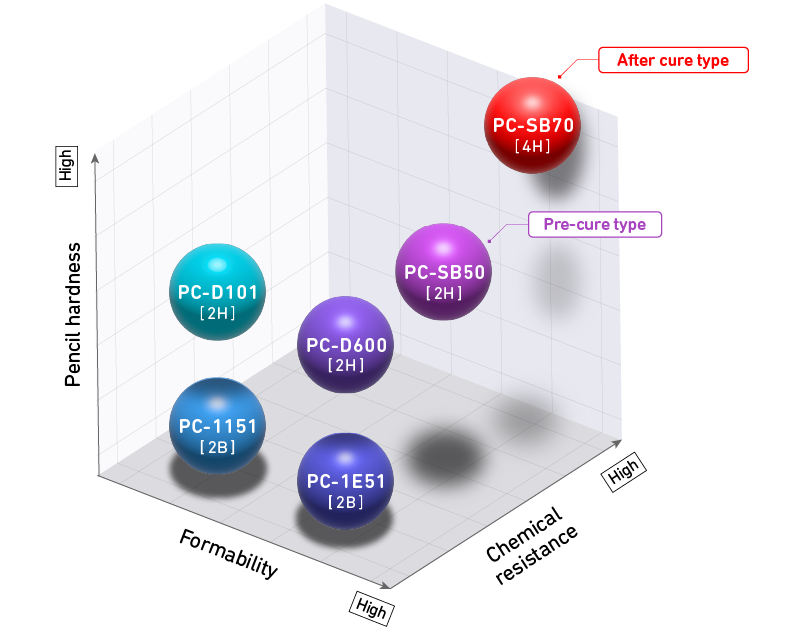

Grade comparison image