Creating a Laptop PC Housing that is Unpainted, has a High Design, is Environmental Friendly, and has Durability.

Polycarbonate resin with added PCR plastic eliminates problems by the design of foreign particles!

Acer Product Development *This article is a story based on actual examples using our products

The need for eco-friendly and recyclable environment-friendly products is increasing. Under the program ‘Earthion’, major computer manufacturer Acer, an early adopter of environment-friendly products, has worked hard to reduce its carbon footprint. At the same time, they also faced problems.

Problem

Issues in design and durability that have arisen due to increased consideration for the environment

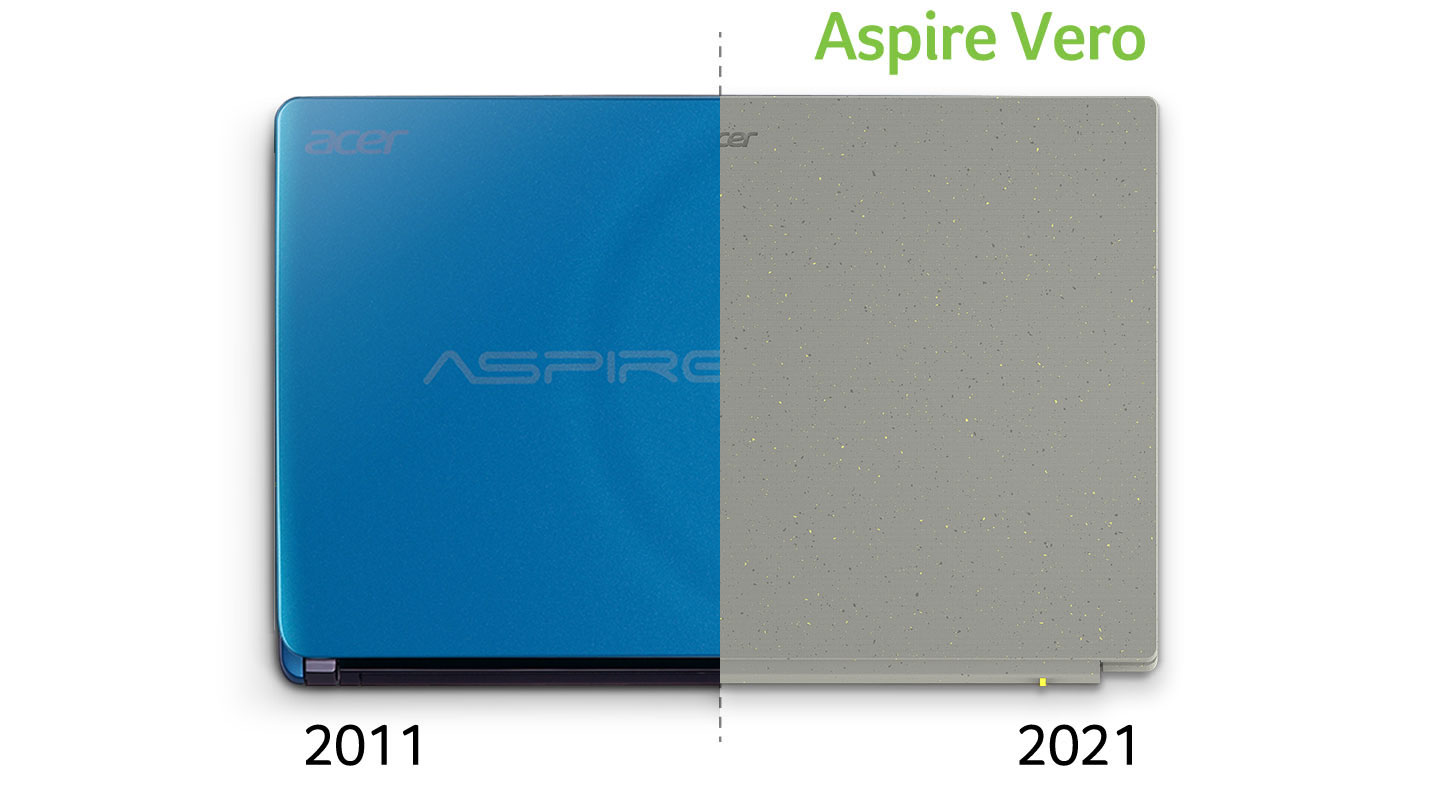

Acer has adopted Teijin’s PCR (Post-Consumer Recycled) plastics to create laptop PC housing and released eco-friendly laptop PCs’. Teijin’s PCR plastics are manufactured by recycling plastic items that have been discarded by households and commercial facilities. In an effort to reduce the environmental impact associated with plastic, a growing number of manufacturers are releasing products that contain recycled plastics.

Actively involved in creating a better product that is eco-friendly, Acer had several concepts including creating a non-painted laptop to limit Volatile Organic Compounds (VOCs) emissions while facing several challenges on the way.

Challenges include:

Being made from waste plastic, PCR plastics contain colored scrap and impurities. If you leave the plastic unpainted, these colors and impurities stand out, creating design challenges.

Increasing the proportion of PCR plastics can also reduce impact resistance, causing durability issues. This would mean that the plastic would be unable to be used in the new product. The case needed to be as durable as those made entirely from virgin plastic.

Summary of the Problem

- The use of PCR blends causes colors and impurities to stand out, making it difficult to achieve a creativity design without painting the housing.

- Increasing the proportion of PCR plastics would reduce impact resistance (durability).