Polycarbonate resin Panlite® for metal joining

Teijin has developed a non-crystalline, non-reinforced metal-bondable polycarbonate resin using its resin development technology and Daicel Miraizu Ltd. metal dissimilar material joining technology called "DLAMP®".

Introduction

As the use of multi-materials, which combine materials with different properties in the right places, progresses, dissimilar material joining, which firmly attaches two different materials without using fastening elements such as screws or adhesives, has been attracting attention in recent years. In particular, technology that joins resin and metal (resin-metal joining technology) can not only make products smaller and lighter, but also contribute to reducing the number of parts, reducing environmental impact, and shortening the manufacturing process. Various research and developments have been carried out.

Filler-reinforced crystalline resins are generally used as resins for resin-metal joining, and amorphous resins such as polycarbonate resins have been considered disadvantageous for joining.

We have successfully developed a metal-resin joining member with strong bonding properties by combining Daicel Miraizu Ltd.'s dissimilar metal material joining technology "DLAMP®" with Teijin's developed metal joining polycarbonate resin. This resin exhibits strong bondability despite being non-reinforced.

Features

■ Join Strength between metal and resin

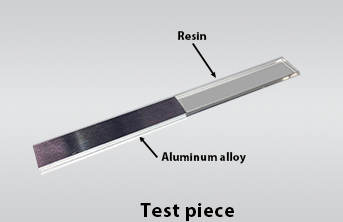

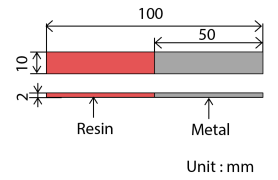

【Test piece】

- Form ; t2.0 x 10 x 100mm

- Metal ; Aluminum alloy (A5052)

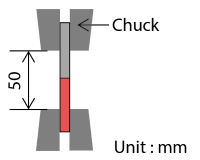

【Test method】

- Tensile test [ISO19095 compliant]

Test condition ; 23℃, 50 %RH

Strain rate ; 10mm/min

Distance between chucks ; 50mm

| Polycarbonate for metal joining | Traditional polycarbonate | |||

|---|---|---|---|---|

| Flame retardant | General | Flame retardant | General | |

| Grade | MN-1200Z | SH-1126Z | MN-3600HA | L-1225L |

| Join strength | 39MPa | 40MPa | 38MPa | 33MPa |

| Flammability (UL94) | 1.5mm V‐0 | - | 1.5mm V‐0 | - |

- High joining strength metal-resin parts can be obtained regardless of the injection molding conditions.

- The resulting metal-resin joined material exhibits high heat cycle properties.

*Please download the document for more information

Application