Products

Polybutylene Naphthalate (PBN) Resin

Introduction and Features

Polybutylene naphthalate (PBN) resin is a crystalline resin made by polycondensation of naphthalene dicarboxylic acid (NDC) and 1,4-butanediol. It is a polyester-based engineering plastic developed using Teijin's unique technology.

Thanks to its characteristic polymer structure of PBN resin it has excellent slidability and chemical resistance, as well as excellent gas and vapor barrier properties.

It has unique features.

Features

This resin has the following unique features thanks to naphthalene skeleton derived from NDC.

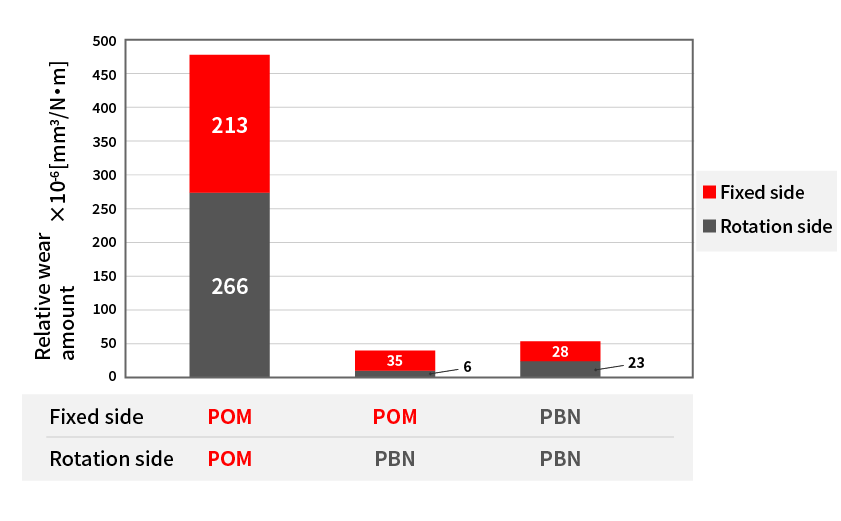

- 1.Excellent abrasion property

- 2.Low elution performance

- 3.Excellent chemical resistance

- 4.Excellent barrier performance against gas and water vapor

- 5.Fast in crystallization speed

Grade Lists

General properties

| Property | Unit | Measurement method | Measurement condition | PBN | PBT |

|---|---|---|---|---|---|

| Specific gravity | g/cm3 | ASTM D792 | - | 1.31 | 1.31 |

| Molding shrinkage (1.5mm) |

% | In-house method | Machine direction | 1.16 | 1.67 |

| Transverse direction | 1.26 | 1.67 | |||

| Tensile strength (max.) | MPa | ASTM D638 | - | 65 | 52 |

| Tensile elongation (max.) | % | ASTM D638 | - | 87 | >200 |

| Flexural modulus | MPa | ASTM D790 | - | 1,920 | 2,550 |

| Impact strength (1/8 inches) |

J/m | ASTM D256 | Notched | 34 | 34 |

| Un-notched | NB | NB | |||

| Surface hardness | - | ASTM D785 | Rockwell | M102 | M75 |

| Melting point | ℃ | DSC method | - | 243 | 225 |

| Glass transition temperature | ℃ | DSC method | - | 78 | 22 |

| Deflection temperature under load | ℃ | ASTM D648 | Load : 1.82MPa | 77 | 58 |

- *Figures described in this table are representative values, not

the values for guaranteeing the performance under specific application.

Meanwhile, the contents are subject to revision without prior notice.

Engineering Service

Abrasion property

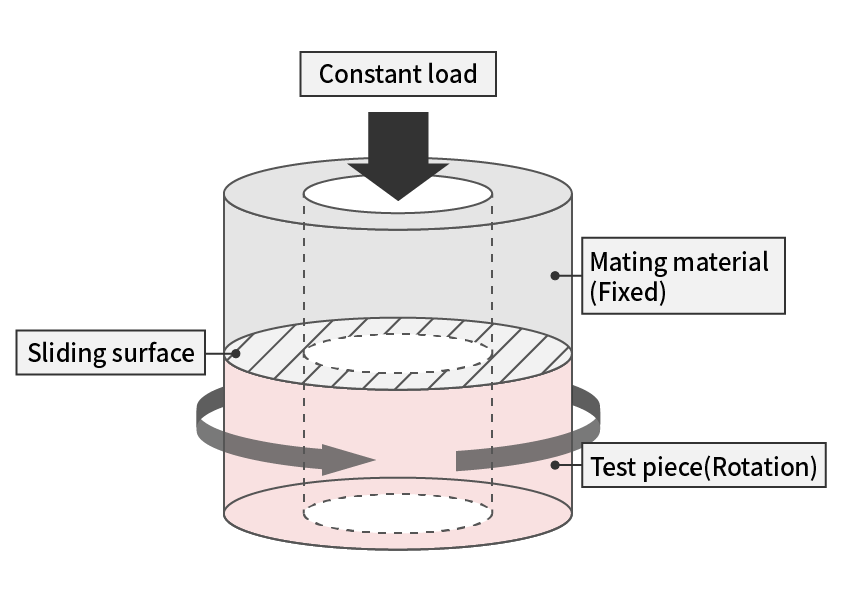

Sliding wear test

[method]Ring of ring

[condition]surface pressure:0.1 MPa

velocity:150 mm/s

sliding distance:900 m

Chemical resistance

| Chemical type | PBN | PPS | PEEK | PES | PET | PBT |

|---|---|---|---|---|---|---|

| Ethylenediamine | A | A | A | D | D | D |

| Ethanol | A | A | A | A | A | A |

| Ethyl acetate | A | A | A | B | B | B |

| Toluene | A | A | A | A | A | B |

| Acetone | A | A | A | D | C | B |

| Xylene | A | A | A | A | A | A |

| Chemical type | PBN | PPS | PEEK | PES | PET | PBT |

|---|---|---|---|---|---|---|

| Ammonia water | A | A | A | A | D | A |

| Hydroxylation Na 10% | A | A | A | A | B | A |

| Hydroxylation Na 30% | A | A | A | A | B | B |

| Chemical type | PBN | PPS | PEEK | PES | PET | PBT |

|---|---|---|---|---|---|---|

| Formic acid | A | A | A | B | C | C |

| Acetic acid | A | A | A | A | B | B |

| Concentrated nitric acid | D | D | D | D | D | D |

| Concentrated hydrochloric acid | A | A | A | B | B | B |

| Chemical type | PBN | PPS | PEEK | PES | PET | PBT |

|---|---|---|---|---|---|---|

| Hydrogen peroxide 30% | A | A | A | A | A | A |

| Hypochlorous acid Na | A | A | A | A | A | A |

| Chloride Na saturated aqueous solution | A | A | A | A | A | A |

- A

- No change (Weight change by 1% or less, tension rupture strength retention by 95% or more, no appearance change)

- B

- Slight change (Weight change by between 1% to 10%, tension rupture strength retention by between 95% to 70%, appearance changed)

- C

- Extensive change (Weight change by 10% or more, tension rupture strength retention by 70% or less, appearance extensively changed)

- D

- Dissolved