Solvent-based Recycling

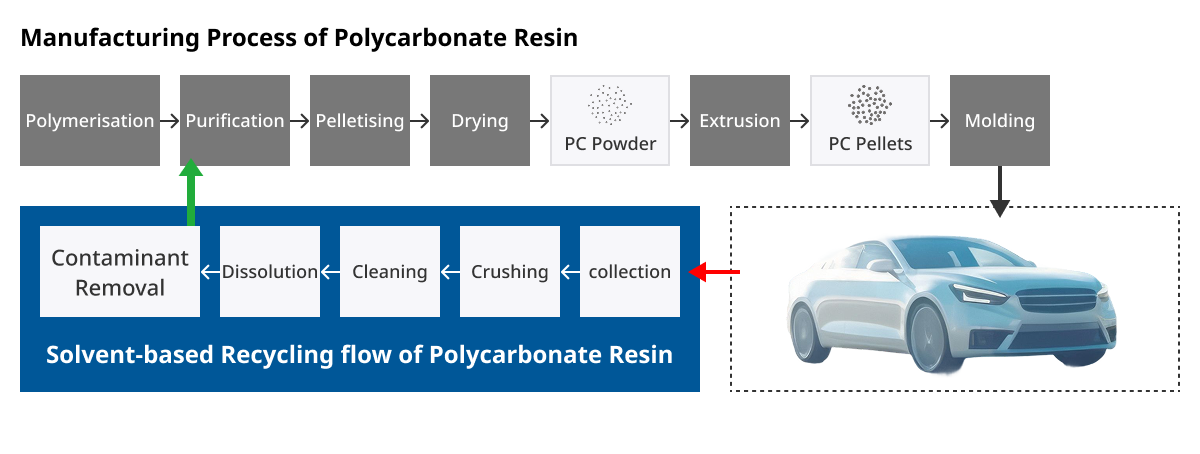

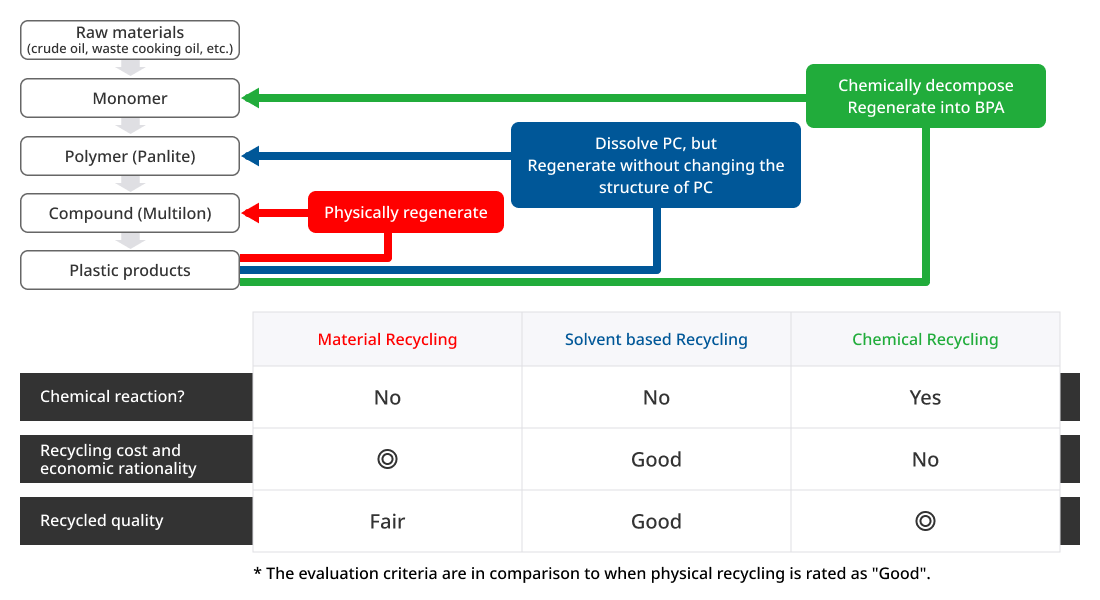

Teijin is developing a solvent-based recycling process as a new technology for the recycling of polycarbonate resin.

This process enables the regeneration of polymers to virgin-comparable quality by dissolving and purifying them with solvents, even from post-consumer recycled (PCR) materials that contain impurities, which have been difficult to handle with conventional mechanical recycling.

Compared to chemical recycling, Teijin’s solvent-based recycling process not only ensures economic feasibility, but also contributes to reducing CO₂ emissions. It is a technology that achieves both reduction of environmental impact and resource circulation, and through this development, Teijin is promoting the advancement of mechanical recycling toward the realization of a sustainable society.

Key Features of the Solvent-based Recycling Process

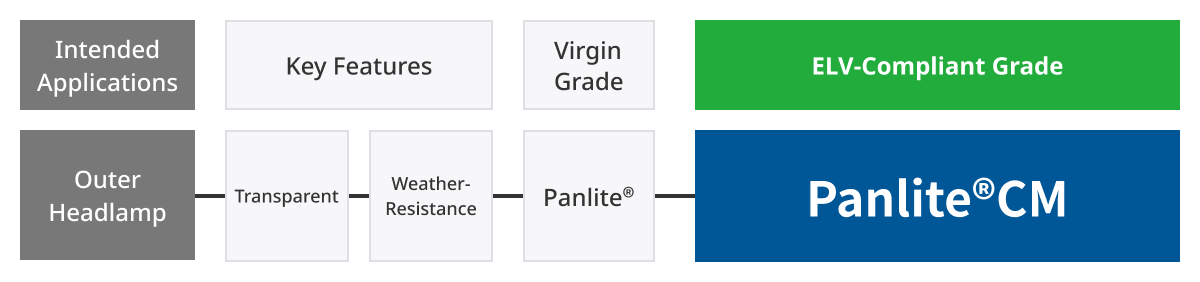

ELV-compliant grade for transparent automotive applications

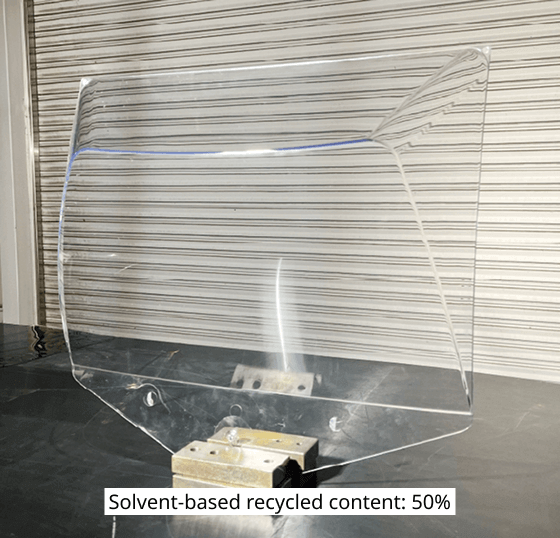

This is an ELV-compliant polycarbonate resin for transparent automotive applications, developed using a solvent-based recycling process that utilizes market-collected materials derived from automotive headlamps.

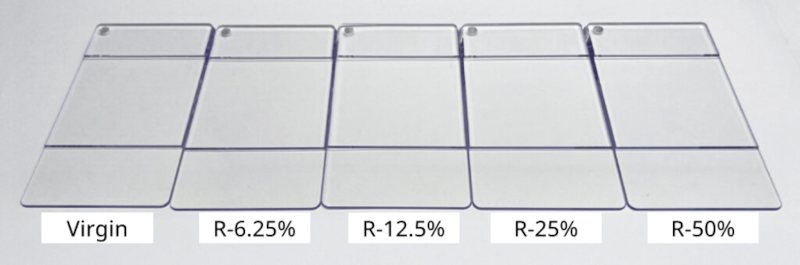

Even with a high ratio of ELV (End-of-Life Vehicle) content, it is capable of maintaining virgin-comparable quality.

Product Overview

- Raw material: r-PC made from market-collected materials derived from automotive headlamps (Recycled content ratio※: 0–50%)

- Base composition: Weather-resistant grade for headlamp applications

- ※Recycling ratio

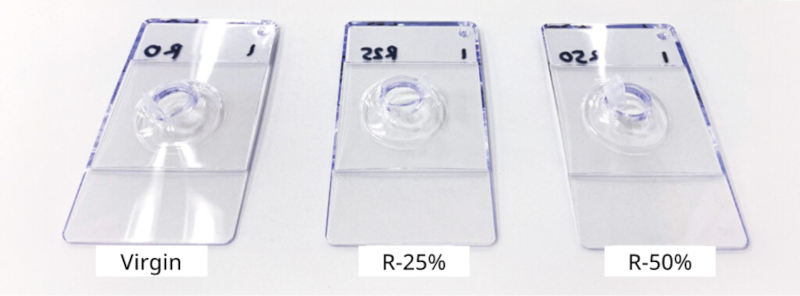

- Surface appearance of molded plate

- Appearance of surface impact test specimen

- Appearance of large molded part

Production Flow of Polycarbonate Resin and the Solvent-based Recycling Process