Special Polyphenylene Sulfide (PPS) Compound Resin SOLFIGA®

Introduction and Features

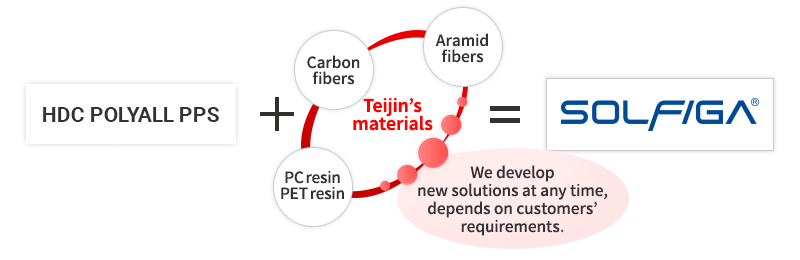

SOLFIGA®, special polyphenylene sulfide (PPS) compound offers unique properties by combining chlorine-free PPS resin of HDC POLYALL and various kinds of materials or technologies originally developed by Teijin.

Concept

By combination of HDC POLYALL's PPS and Teijin's original technologies, the special PPS compounded products offer new solutions to meet wide variety of requirements such as weight reduction, improvement of appearance or adding multiple functions.

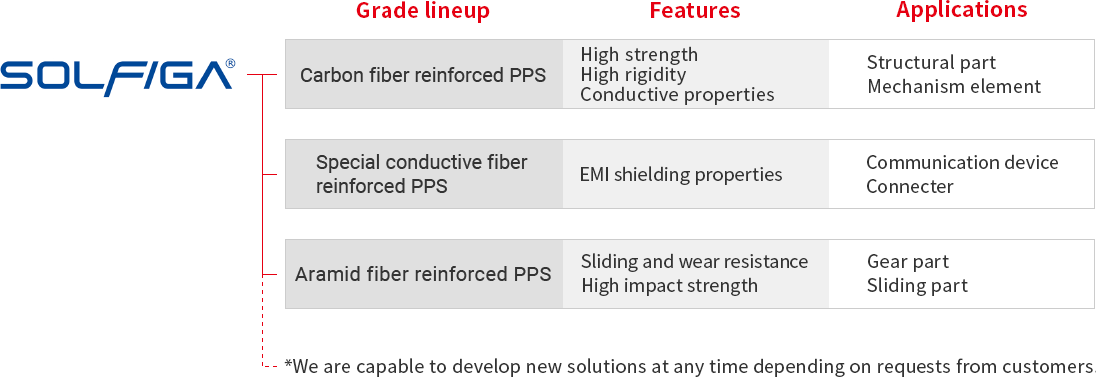

Grade Lists

Grade lists

SOLFIGA® lineup incorporates Teijin's own compounding technologies and materials such as carbon fibers, special conductive fibers or aramid fibers.

Engineering Service

Technical properties

PPS carbon fiber reinforced grade

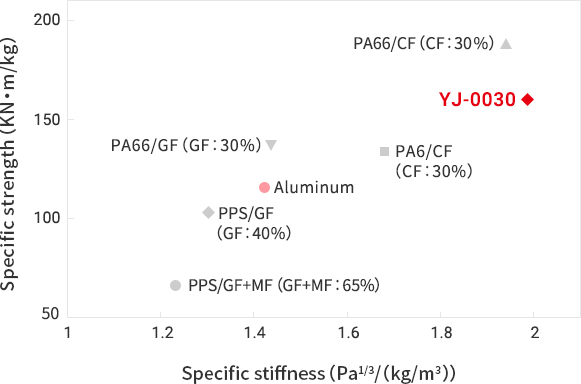

Carbon fiber reinforced grade is established by combining HDC POLYALL's PPS and Teijin's carbon fiber utilizing Teijin's compounding technology, realizing weight reduction and strength (Figure.1), low water absorption (Table.1) and dimensional stability.

Figure.1 Mechanical strength of PPS/CF (YJ-0030).

Table.1 Comparative water absorption amount of PPS/CF (YJ-0030).

| Teijin PPS/CF (YJ-0030) |

PA6/CF (CF:30%) |

PA66/CF (CF:30%) |

PA66/GF (GF30%) |

PPS/GF (GF:40%) |

PPSGF+MF (GF+MF:65%) |

|

|---|---|---|---|---|---|---|

| Comparative water absorption |

Good 〇 (1.3) |

Not Good △ (37.5) |

Bad × (100) |

Not Good △ (37.5) |

Good 〇 (1.3) |

Good 〇 (1.3) |

- *Water absorption coefficient when the rate of carbon fiber reinforced PA66 is taken as 100.

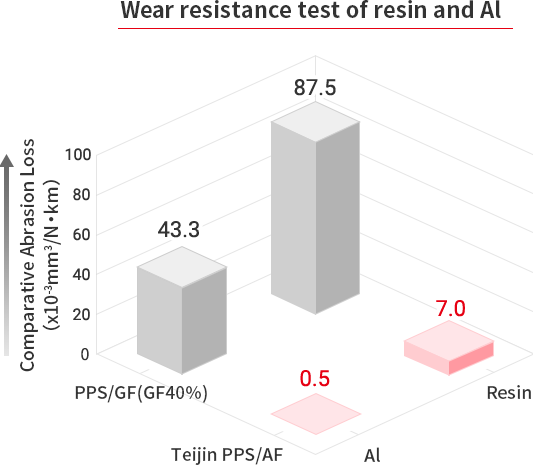

PPS aramid fiber reinforced grade

Aramid fiber reinforced grade is established by combining HDC POLYALL's PPS and Teijin's aramid

fiber's features.

It has excellent wear resistance especially against soft metal such as

aluminum. Protection of soft metal from abrasion is expected (Figure.2).

Figure.2 Wear resistance of PPS/AF (YJ-0010)