Polyethylene Terephthalate (PET) Resin

Introduction and Features

Polyethylene terephthalate (PET) resin is used for various of applications, such as packaging, industrial

parts and sheets etc. PET has excellent characteristics such as high transparency, high mechanical and

excellent gas barrier properties.

Teijin has newly developed / introduced PET resin, which employs

titanium compound as catalyst. It is a completely new catalyst that solves the drawbacks of conventional

titanium catalysts in addition Teijin also provide antimony catalyst PET resin.

- *Please note that this page is limited to resin materials.

We handle sheet and film products in polycarbonate (PC) only.

Feature

The features of new titanium catalyst PET are as below.

Please contact us for

details.

Titanium catalyst PET

- 1.Stable supply:

Antimony and germanium compounds are commonly used as PET polymerization catalysts, however these metals are distributed only in limited areas.

- 2.Safety:

Titanium is one of biocompatible materials that has been used for dental purposes.

- 3.Environment friendly:

Only a small amount of our titanium compound are used compared to other catalysts. (approximately 1/20 the amount of antimony compound, and approximately 1/10 the amount of germanium compound). Only trace residue would be observed in incineration process.

- 4.Aesthetic appearance:

PET resin produced with our titanium catalyst has excellent color and clarity.

- 5.Wide assortment:

Various grades from homo to copolymer PET are available and molecular weight can also be selected according to the application.

Antimony catalyst PET

- 1.In addition to the homo PET resin, a variety of specialty PET resins with enhanced properties such as transparency and gas barrier through copolymerization with a third component are available. Wide range of molecular weight product portfolio as well as various mechanical properties and moldability are also applicable.

Grade Lists

Food hygiene

- Japan

Some grades meet requirements of various notices of the Food Sanitation Act, and comply to the positive list of the Japan Hygienic Olefin and Styrene Plastics Association

(Please contact us for details.)

- USA

Some grades meet FDA CFR §177.1630 standards

(Please contact us for details.)

Titanium catalyst grades

| Property | Unit | Measurement method | TRN-MTJ | TRN-8550FF | TRN-RTJ | TRN-8580FH |

|---|---|---|---|---|---|---|

| Intrinsic viscosity | dl/g | In-house method | 0.53 | 0.77 | 0.64 | 0.80 |

| Color (b-value) |

- | In-house method | -3 | -1 | -2 | 0 |

| Melting point | ℃ | DSC | 254 | 252 | 254 | 252 |

| Crystallization speed | Fast | Fast | Fast | Fast | ||

| Comonomer | None | None | None | None | ||

| Applications |

|

|

|

|

||

| Property | Unit | Measurement method | TRN-RTJC | TRN-8580FC | TRN-8580FC5 | TRN-8385FC |

|---|---|---|---|---|---|---|

| Intrinsic viscosity | dl/g | In-house method | 0.64 | 0.81 | 0.76 | 0.81 |

| Color (b-value) |

- | In-house method | -2 | 0 | -1 | -1 |

| Melting point | ℃ | DSC | 249 | 247 | 240 | 238 |

| Crystallization speed | Somewhat fast | Somewhat fast | Slow | Slow | ||

| Comonomer | Present | Present | Present | Present | ||

| Applications |

|

|

|

|

||

Antimony catalyst grades

| Property | Unit | Measurement method | TRN-8762 | TR-BB |

|---|---|---|---|---|

| Intrinsic viscosity | dl/g | In-house method | 0.80 | 0.88 |

| Color (b-value) |

- | In-house method | -4 | -4 |

| Melting point | ℃ | DSC | 251 | 245 |

| Crystallization speed | Fast | Somewhat fast | ||

| Comonomer | None | Present | ||

| Applications |

|

|

||

| Property | Unit | Measurement method | TRN-3324AC | TRN-8384AC | TRN-3320AC | TRN-8380AC |

|---|---|---|---|---|---|---|

| Intrinsic viscosity | dl/g | In-house method | 0.64 | 0.89 | 0.67 | 0.88 |

| Color (b-value) |

- | In-house method | 0 | -2 | -2 | -2 |

| Melting point | ℃ | DSC | 243 | 238 | 229 | 225 |

| Crystallization speed | Slow | Slow | Extremely slow | Extremely slow | ||

| Comonomer | Present | Present | Present | Present | ||

| Applications |

|

|

|

|

||

- *As of July 2022

Engineering Service

Titanium catalyst PET resin can be used for fiber and biaxially oriented film as well as for injection molding, injection blow molding and extrusion molding.

Features

- 1.Antimony-free

Does not contain any antimony-based catalyst, which is commonly used for polyesters.

Molding use : Heavy metal*1-free applications are available.

Fiber use : No harmful heavy metals are eluted even in post-processing steps such as dying and alkali volume reduction.

- *1Defined as a metal having a specific gravity of 5 or more.

- 2.Increased productivity

With minimum deposits around the holes of the spinners, cleaning cycle can be significantly extended.

Cleaning cycle of film/sheet manufacturing rolls and injection molds are also extended as only few amounts of white powders adhere in the processes.

(Please contact us for details as effects depend on grades.)

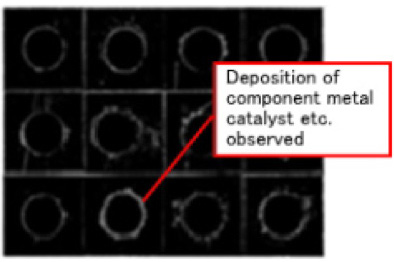

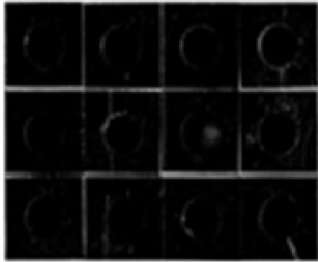

Spinneret hole after spinning at 295℃ for 48hours

With heavy-metal-free polyester chips

With chips comprising antimony-based catalyst