Products

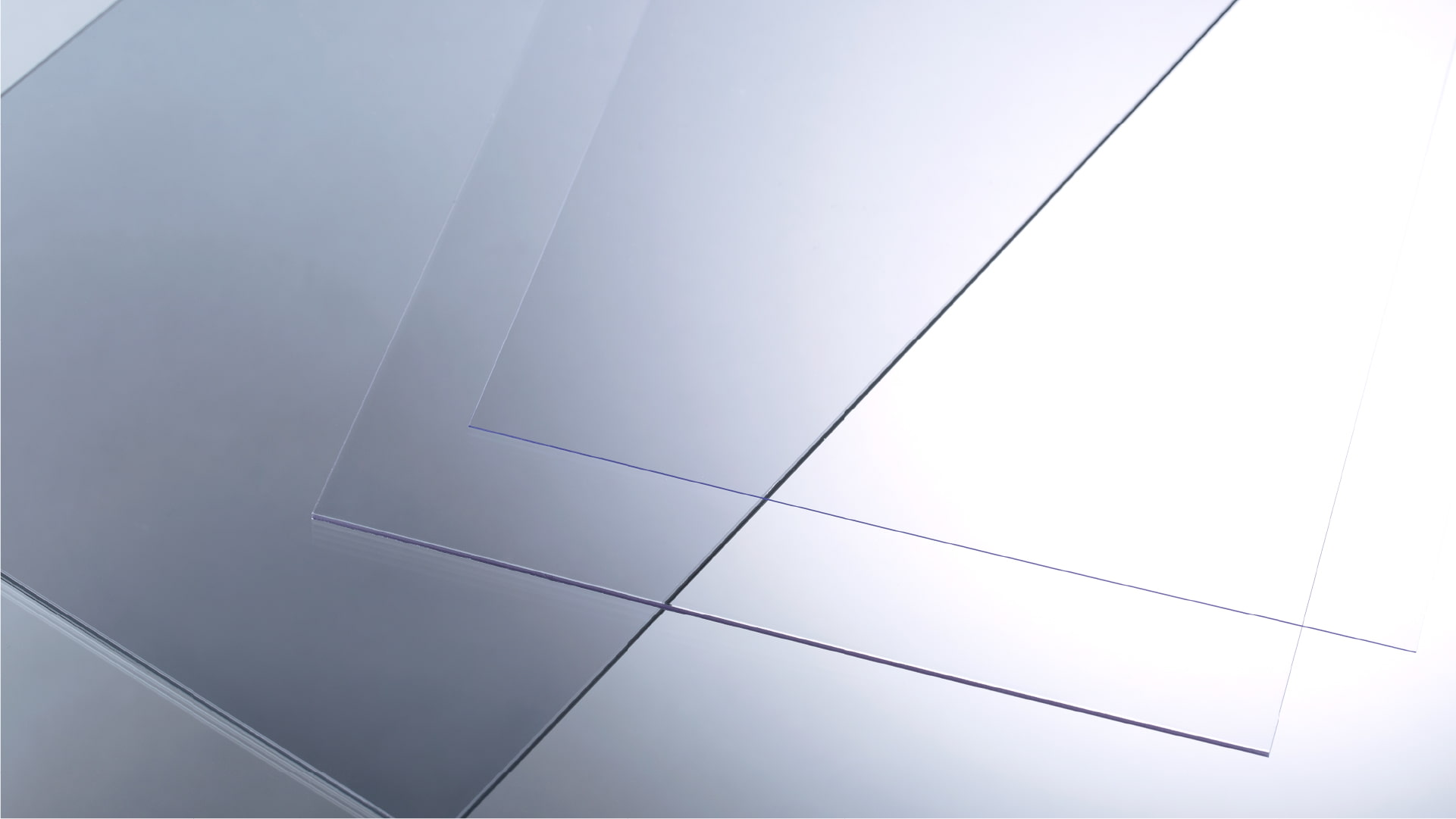

Polycarbonate Resin Panlite® Sheet & Film

Introduction and Features

Polycarbonate resin "Panlite®" sheets and films, which have excellent characteristics such as heat resistance, impact resistance, and high transmittance, are used for automobile parts, electrical and electronic parts, printing nameplates, etc. "Panlite®" sheets are available in various thicknesses, from thin films to thick sheets. You will find products, in our portfolio, which meet your requirements such as pre-hard coated and higher pencil hardness (multi-layered).

Focus Products

Grade Lists

- Light guide film

- PC/PMMA Multi Layer sheet

- Standard grades

- Weather resistant grades

- HUD dust cover sheet

- Heat bendable pre-hard coated sheet

- Multi Layer and hard coat sheet