Products

Brominated Flame Retardant FG Series

Introduction and Features

FG series is a brominated flame retardant which Teijin developed after many years of researches, and it is effective for plastics used in various fields including electric appliances, automobiles and construction materials.

Features

| Grade | Chemical structure | Main application |

|---|---|---|

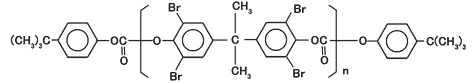

| FG-7000 |

|

PET, PBT, ABS PC, PC/ABS |

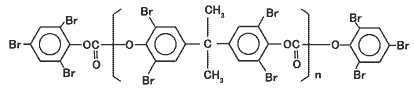

| FG-7500 |

|

PET, PBT, ABS PC, PC/ABS |

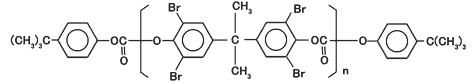

| FG-8500 |

|

PET, PBT, PC, PC/ABS, ABS |

Grade Lists

| Grade | Appearance | Melting point |

5% Weight loss temperature*1 ℃ |

Bromine content % |

Specific gravity |

Solubility*2 | |||

|---|---|---|---|---|---|---|---|---|---|

| Water | Methanol | Acetone | Benzene | ||||||

| FG-7000 | White powder | 230 - 250 | 444 | 52.8 | 1.9 | × | × | △ | △ |

| FG-7500 | White powder | 208 - 228 | 442 | 52.1 | 1.9 | × | × | △ | △ |

| FG-8500 | White powder | 205 - 225 | 446 | 58 | 2.1 | × | × | △ | △ |

- *1Ramp up at 20℃/min under N2 atmosphere.

- *2○ : soluble △ : hardly soluble × : insoluble

The values on the table are representative, not guaranteed.

Engineering Service

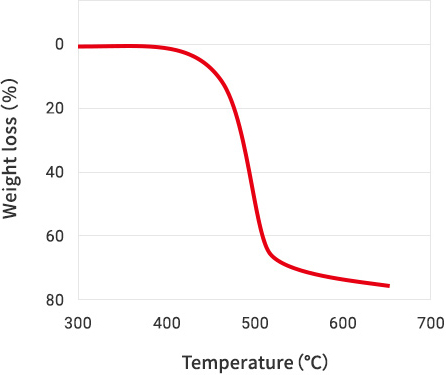

FG-7000

Thermogravimetric analysis

Atmosphere : N2

Heating rate : 20℃/min

| Weight loss | Temperature |

|---|---|

| 5% | 444℃ |

| 10% | 461℃ |

| 20% | 478℃ |

Applications

- 1.Non-reinforced PBT

- (1)Resin and additive

-

- Resin

- : PBT (TRB-H, Teijin)

-

- Flame retardant

- : FG-7000

-

- Auxiliary compound

- : Sb2O3 (ATOX-S)

-

- (2)Processing conditions

-

- Extrusion

- : 30mm extruder, extrusion temperature at 240℃

-

- Injection molding

- : 3 oz/shot injection molding machine, molding temperature at 240℃

-

- (3)Properties of sample compound with non-reinforced PBT

| Property | Unit | Measurement method | Blank | No.1 | No.2 | No.3 | No.4 |

|---|---|---|---|---|---|---|---|

| PBT | Weight part | - | 100 | 100 | 100 | 100 | 100 |

| FG-7000 | Weight part | - | 0 | 8 | 10 | 12 | 14 |

| Sb2O3 | Weight part | - | 0 | 4 | 5 | 6 | 7 |

| Flammability | - | UL-94 (6.4mm) | HB | V-2 | V-2 | V-0 | V-0 |

| - | UL-94 (3.2mm) | HB | V-2 | V-2 | V-0 | V-0 | |

| - | UL-94 (1.6mm) | HB | HB | V-2 | V-2 | V-0 | |

| OI | % | ASTM D-2863 | 21.4 | 23.5 | 24.5 | 25.1 | 26.6 |

| Specific gravity | - | ASTM D-792 | 1.31 | 1.37 | 1.39 | 1.40 | 1.42 |

| Yield strength | MPa (kgf/cm2) |

ASTM D-638 | 50 (510) |

55 (560) |

57 (580) |

59 (600) |

60 (610) |

| Elongation | % | ASTM D-638 | 320 | 20 | 15 | 13 | 12 |

| Flexural strength | MPa (kgf/cm2) |

ASTM D-790 | 83 (850) |

89 (910) |

92 (940) |

94 (960) |

95 (970) |

| Flexural modulus | MPa (kgf/cm2) |

ASTM D-790 | 2,230 (22,700) |

2,540 (25,900) |

2,600 (26,500) |

2,690 (27,400) |

2,710 (27,600) |

| Impact strength | J/m (kgf・cm/cm) |

ASTM D-256 (3.2mm) |

26 (2.7) |

15 (1.5) |

13 (1.3) |

12 (1.2) |

12 (1.2) |

| J/m (kgf・cm/cm) |

ASTM D-256 (6.4mm) |

26 (2.7) |

15 (1.5) |

15 (1.5) |

13 (1.3) |

13 (1.3) |

|

| Heat distortion temperature |

℃ | ASTM D-648 Load 1.82MPa (18.6kgf/cm2) |

55 | 60 | 62 | 65 | 68 |

- 2.Reinforced PBT

- (1)Resin and additive

-

- Resin

- : PBT (TRB-J, Teijin)

-

- Glass fiber

- : Chopped strand (Nitto Boseki Co., Ltd.)

-

- Flame retardant

- : FG-7000

-

- Auxiliary compound

- : Sb2O3 (ATOX-S)

-

- (2)Processing conditions

-

- Extrusion

- : 30mm extruder, extrusion temperature at 250℃

-

- Injection molding

- : 3oz/shot injection molding machine, molding temperature at 250℃

-

- (3)Properties of sample compound with reinforced PBT

| Property | Unit | Measurement method | Blank | No.1 | No.2 | No.3 |

|---|---|---|---|---|---|---|

| PBT | Weight % | - | 70.0 | 61.0 | 56.5 | 50.5 |

| Glass fiber | Weight % | - | 30.0 | 30.0 | 30.0 | 30.0 |

| FG-8500 | Weight % | - | 0 | 6.0 | 9.0 | 13.0 |

| Sb2O3 | Weight % | - | 0 | 3.0 | 4.5 | 6.5 |

| Flammability | - | UL-94 (3.2mm) | HB | HB | V-0 | V-0 |

| - | UL-94 (1.6mm) | HB | HB | V-0 | V-0 | |

| - | UL-94 (0.8mm) | HB | V-2 | V-2 | V-0 | |

| OI | % | ASTM D-2863 | 19.5 | 28.0 | 31.3 | 33.4 |

| Specific gravity | - | ASTM D-792 | 1.51 | 1.59 | 1.62 | 1.70 |

| Rupture strength | MPa (kgf/cm2) |

ASTM D-638 | 130 (1,330) |

127 (1,300) |

126 (1,280) |

123 (1,250) |

| Elongation | % | ASTM D-638 | 3 | 2 | 2 | 2 |

| Flexural strength | MPa (kgf/cm2) |

ASTM D-790 | 199 (2,030) |

194 (1,980) |

191 (1,950) |

186 (1,900) |

| Flexural modulus | MPa (kgf/cm2) |

ASTM D-790 | 8,140 (83,000) |

8,830 (90,000) |

9,020 (92,000) |

9,510 (97,000) |

| Impact strength | J/m (kgf・cm/cm) |

ASTM D-256 (3.2mm) |

65 (6.6) |

55 (5.6) |

52 (5.3) |

53 (5.4) |

| J/m (kgf・cm/cm) |

ASTM D-256 (6.4mm) |

74 (7.5) |

59 (6.0) |

57 (5.8) |

52 (5.3) |

|

| Heat distortion temperature |

℃ | ASTM D-648 Load 1.82MPa (18.6kgf/cm2) |

209 | 210 | 210 | 210 |

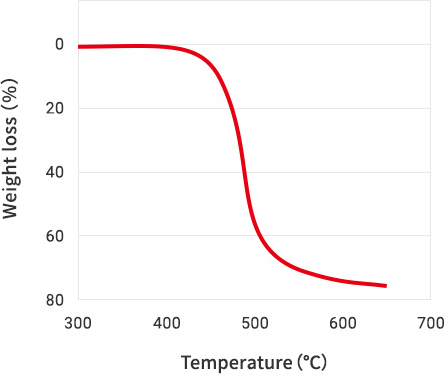

FG-7500

Thermogravimetric analysis

Atmosphere : N2

Heating rate : 20℃/min

| Weight loss | Temperature |

|---|---|

| 5% | 442℃ |

| 10% | 459℃ |

| 20% | 477℃ |

Applications

- 1.Non-reinforced PBT

- (1)Resin and additive

-

- Resin

- : PBT (TRB-H, Teijin)

-

- Flame retardant

- : FG-7500

-

- Auxiliary compound

- : Sb2O3 (ATOX-S)

-

- (2)Processing conditions

-

- Extrusion

- : 30mm extruder, extrusion temperature at 240℃

-

- Injection molding

- : 3 oz/shot injection molding machine, molding temperature at 240℃

-

- (3)Properties of sample compound with non-reinforced PBT

| Property | Unit | Measurement method | Blank | No.1 | No.2 | No.3 | No.4 |

|---|---|---|---|---|---|---|---|

| PBT | Weight part | - | 100 | 100 | 100 | 100 | 100 |

| FG-7500 | Weight part | - | 0 | 10.0 | 12.0 | 14.5 | 17.0 |

| Sb2O3 | Weight part | - | 0 | 5.0 | 6.0 | 7.3 | 8.5 |

| Flammability | - | UL-94 (6.4mm) | HB | V-2 | V-0 | V-0 | V-0 |

| - | UL-94 (3.2mm) | HB | V-2 | V-2 | V-0 | V-0 | |

| - | UL-94 (1.6mm) | HB | HB | V-2 | V-2 | V-0 | |

| OI | % | ASTM D-2863 | 21.4 | 24.1 | 25.8 | 26.8 | 27.6 |

| Specific gravity | - | ASTM D-792 | 1.31 | 1.39 | 1.40 | 1.41 | 1.43 |

| Yield strength | MPa (kgf/cm2) |

ASTM D-638 | 50 (510) |

58 (590) |

59 (600) |

59 (600) |

60 (610) |

| Elongation | % | ASTM D-638 | 320 | 32 | 30 | 25 | 25 |

| Flexural strength | MPa (kgf/cm2) |

ASTM D-790 | 83 (850) |

88 (900) |

90 (920) |

92 (940) |

93 (950) |

| Flexural modulus | MPa (kgf/cm2) |

ASTM D-790 | 2,230 (22,700) |

2,580 (26,300) |

2,650 (27,000) |

2,680 (27,300) |

2,690 (27,400) |

| Impact strength | J/m (kgf・cm/cm) |

ASTM D-256 (3.2mm) |

26 (2.7) |

18 (1.8) |

17 (1.7) |

16 (1.6) |

16 (1.6) |

| J/m (kgf・cm/cm) |

ASTM D-256 (6.4mm) |

26 (2.7) |

18 (1.8) |

16 (1.6) |

16 (1.6) |

16 (1.6) |

|

| Heat distortion temperature |

℃ | ASTM D-648 Load 1.82MPa (18.6kgf/cm2) |

55 | 62 | 65 | 67 | 68 |

- 2.ABS

- (1)Resin and additive

-

- Resin

- : ABS (Tufrex TFX-410)

-

- Flame retardant

- : FG-7500

-

- Auxiliary compound

- : Sb2O3 (ATOX-S)

-

- (2)Processing conditions

-

- Extrusion

- : 30mm extruder, extrusion temperature at 230℃

-

- Injection molding

- : 3oz/shot injection molding machine, molding temperature at 230℃

-

- (3)Properties of sample compound with reinforced ABS

| Property | Unit | Measurement method | Blank | No.1 | No.2 | No.3 | No.4 |

|---|---|---|---|---|---|---|---|

| ABS | Weight part | - | 100 | 100 | 100 | 100 | 100 |

| FG-7500 | Weight part | - | 0 | 20.0 | 22.5 | 25.0 | 27.5 |

| Sb2O3 | Weight part | - | 0 | 4.0 | 4.5 | 5.0 | 5.5 |

| Flammability | - | UL-94 (6.4mm) | HB | V-0 | V-0 | V-0 | V-0 |

| - | UL-94 (3.2mm) | HB | V-2 | V-2 | V-2 | V-0 | |

| - | UL-94 (1.6mm) | HB | HB | V-2 | V-2 | V-0 | |

| OI | % | ASTM D-2863 | 18.3 | 24.3 | 25.3 | 25.8 | 26.3 |

| Specific gravity | - | ASTM D-792 | 1.07 | 1.17 | 1.19 | 1.20 | 1.21 |

| Yield strength | MPa (kgf/cm2) |

ASTM D-638 | 43 (440) |

45 (460) |

46 (470) |

46 (470) |

48 (490) |

| Elongation | % | ASTM D-638 | 27 | 17 | 16 | 16 | 14 |

| Flexural strength | MPa (kgf/cm2) |

ASTM D-790 | 74 (750) |

72 (730) |

72 (730) |

73 (740) |

73 (740) |

| Flexural modulus | MPa (kgf/cm2) |

ASTM D-790 | 2,450 (25,000) |

2,310 (23,600) |

2,330 (23,800) |

2,390 (24,400) |

2,420 (24,700) |

| Impact strength | J/m (kgf・cm/cm) |

ASTM D-256 (3.2mm) |

90 (9.2) |

22 (2.2) |

16 (1.6) |

14 (1.4) |

14 (1.4) |

| J/m (kgf・cm/cm) |

ASTM D-256 (6.4mm) |

118 (12.0) |

27 (2.8) |

24 (2.4) |

25 (2.5) |

20 (2.0) |

|

| Heat distortion temperature |

℃ | ASTM D-648 Load 1.82MPa (18.6kgf/cm2) |

84 | 86 | 88 | 92 | 93 |

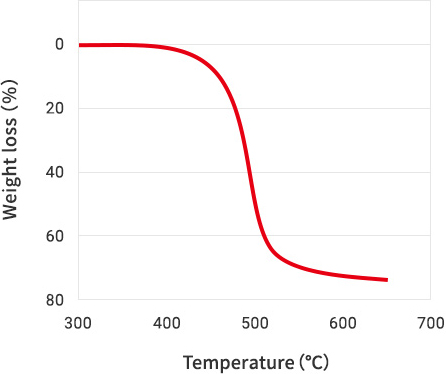

FG-8500

Thermogravimetric analysis

Atmosphere : N2

Heating rate : 20℃/min

| Weight loss | Temperature |

|---|---|

| 5% | 446℃ |

| 10% | 461℃ |

| 20% | 476℃ |

Applications

- 1.Non-reinforced PBT

- (1)Resin and additive

-

- Resin

- : PBT (TRB-H, Teijin)

-

- Flame retardant

- : FG-8500

-

- Auxiliary compound

- : Sb2O3 (ATOX-S)

-

- (2)Processing conditions

-

- Extrusion

- : 30mm extruder, extrusion temperature at 240℃

-

- Injection molding

- : 5oz/shot injection molding machine, molding temperature at 240℃

-

- (3)Properties of sample compound with non-reinforced PBT

| Property | Unit | Measurement method | Blank | No.1 | No.2 | No.3 |

|---|---|---|---|---|---|---|

| PBT | Weight part | - | 100 | 100 | 100 | 100 |

| FG-8500 | Weight part | - | - | 12.0 | 14.0 | 16.0 |

| Sb2O3 | Weight part | - | - | 6.0 | 7.0 | 8.0 |

| Flammability | - | UL-94 (3.2mm) | HB | V-0 | V-0 | V-0 |

| - | UL-94 (1.6mm) | HB | V-2 | V-0 | V-0 | |

| - | UL-94 (0.8mm) | HB | V-2 | V-2 | V-0 | |

| OI | % | ASTM D-2863 | 21.4 | 26.4 | 27.6 | 28.6 |

| Specific gravity | - | ASTM D-792 | 1.31 | 1.41 | 1.43 | 1.45 |

| Yield strength | MPa (kgf/cm2) |

ASTM D-638 | 50 (510) |

59 (600) |

60 (610) |

61 (620) |

| Elongation | % | ASTM D-638 | 320 | 20 | 18 | 17 |

| Flexural strength | MPa (kgf/cm2) |

ASTM D-790 | 83 (850) |

91 (930) |

97 (990) |

99 (1,010) |

| Flexural modulus | MPa (kgf/cm2) |

ASTM D-790 | 2,230 (22,700) |

2,670 (27,200) |

2,700 (27,500) |

2,730 (27,800) |

| Impact strength | J/m (kgf・cm/cm) |

ASTM D-256 (3.2mm) |

26 (2.7) |

14 (1.4) |

14 (1.4) |

14 (1.4) |

| J/m (kgf・cm/cm) |

ASTM D-256 (6.4mm) |

26 (2.7) |

16 (1.6) |

16 (1.6) |

15 (1.5) |

|

| Heat distortion temperature |

℃ | ASTM D-648 Load 1.82MPa (18.6kgf/cm2) |

55 | 67 | 68 | 68 |

| MFR | g/10min | JISK-7210 275℃×0.0319MPa (0.325kgf/cm2) |

4.5 | 9.2 | 9.4 | 9.5 |

- 2.Reinforced PBT

- (1)Resin and additive

-

- Resin

- : PBT (Product nameTRB-J from Teijin)

-

- Glass fiber

- : Chopped strand (Nitto Boseki Co., Ltd.)

-

- Flame retardant

- : FG-8500

-

- Auxiliary compound

- : Sb2O3 (ATOX-S)

-

- (2)Processing conditions

-

- Extrusion

- : 30mm extruder, extrusion temperature 250℃

-

- Injection molding

- : 5oz/shot injection molding machine, molding temperature 250℃

-

- (3)Properties of sample compound with reinforced PBT

| Property | Unit | Measurement method | Blank | No.1 | No.2 | No.3 |

|---|---|---|---|---|---|---|

| PBT | Weight % | - | 70.0 | 59.5 | 56.5 | 53.5 |

| Glass fiber | Weight % | - | 30.0 | 30.0 | 30.0 | 30.0 |

| FG-8500 | Weight % | - | - | 7.0 | 9.0 | 11.0 |

| Sb2O3 | Weight % | - | - | 3.5 | 4.5 | 5.5 |

| Flammability | - | UL-94 (3.2mm) | HB | V-0 | V-0 | V-0 |

| - | UL-94 (1.6mm) | HB | V-1 | V-0 | V-0 | |

| - | UL-94 (0.8mm) | HB | V-2 | V-2 | V-0 | |

| OI | % | ASTM D-2863 | 19.5 | 27.0 | 29.7 | 31.5 |

| Specific gravity | - | ASTM D-792 | 1.53 | 1.63 | 1.66 | 1.70 |

| Rupture strength | MPa (kgf/cm2) |

ASTM D-638 | 130 (1,330) |

126 (1,280) |

124 (1,260) |

123 (1,250) |

| Elongation | % | ASTM D-638 | 3 | 2 | 2 | 2 |

| Flexuralstrength | MPa (kgf/cm2) |

ASTM D-790 | 199 (2,030) |

190 (1,940) |

191 (1,950) |

193 (1,970) |

| Flexural modulus | MPa (kgf/cm2) |

ASTM D-790 | 8,140 (83,000) |

8,730 (89,000) |

8,830 (90,000) |

8,920 (91,000) |

| Impact strength | J/m (kgf・cm/cm) |

ASTM D-256 (3.2mm) |

65 (6.6) |

53 (5.4) |

52 (5.3) |

52 (5.3) |

| J/m (kgf・cm/cm) |

ASTM D-256 (6.4mm) |

74 (7.5) |

62 (6.3) |

60 (6.1) |

59 (6.0) |

|

| Heat distortion temperature |

℃ | ASTMD-648 Load 1.82MPa (18.6kgf/cm2) |

210 | 210 | 210 | 210 |