Polycarbonate resin Panlite® for LDS

Teijin has developed a low dielectric polycarbonate resin that excels in supporting the Laser Direct Structuring (LDS) method, which is one of the processing techniques for 3D circuitry (Molded Interconnect Devices - MID). This resin offers excellent low dielectric properties, enabling lightweighting, thinning, and greater design flexibility of devices while minimizing transmission losses.

Introduction

■ About MID (Molded Interconnect Device)

A three-dimensional resin molded product with electrodes and circuits formed on its surface.

This technology is gaining attention for its ability to reduce the number of components on printed circuit boards (PCBs) and flexible circuit boards (FPCs). By doing so, it contributes to making products lighter and thinner. Additionally, it enhances the flexibility in the design of electrical appliances, allowing for innovative shapes and new designs.

■ About LDS (Laser Direct Structuring)

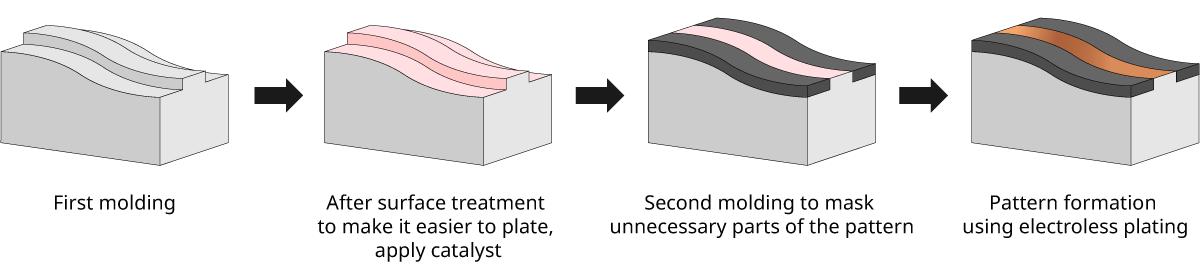

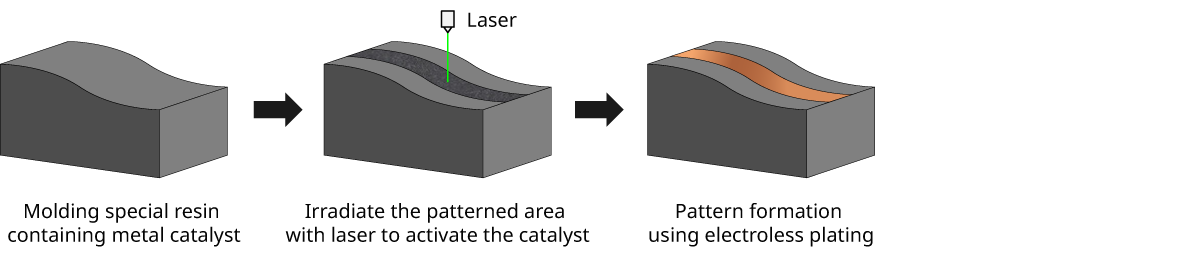

MID processing methods can be broadly classified into two-shot molding and one-shot molding.

Of these, the one-shot molding (LDS) is becoming more widely used because, compared to the two-shot molding, ① only one mold is required, ② the process is completed in three steps: molding → laser irradiation → electroless copper plating (no catalyst application required), and ③ the circuit pattern can be easily changed just by changing the laser data.

Teijin is developing a lineup of polycarbonate materials that are compatible with this one-shot molding (LDS) .

- two-shot molding

- one-shot molding (LDS)

Features of TEIJIN’s polycarbonate for LDS

- Good plating deposition and adhesion.

- Low dielectric properties and ensures stable communication performance with little transmission loss.

- Excellent strength and insulation thermal conductivity, making it suitable for various electrical and electronic equipment parts.

| Flammability (V-0 thickness) |

Feature | Grade | |

|---|---|---|---|

| Non-reinforced | - | High impact strength | MX‐1072A |

| ○*(0.6mm) | Low dielectric | MW-4560A | |

| Reinforced | ○(0.6mm) | Low dielectric | GYV‐3520A |

| ○*(1.5mm) | Thermal conductivity | DN‐5326BA |

- *Preparing for UL94 certification