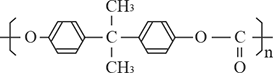

Polycarbonte (PC) Resin Panlite® & Multilon®

Introduction and Features

Panlite® is Japan's first polycarbonate resin commercialized by Teijin. Since then, we have continued to improve the quality of Panlite® and explore new applications for it, and have also developed Multilon®, a PC/ABS based polymer alloy, which has produced many successful results. Now Panlite® is widely accepted as one of the world's premier engineering plastics.Panlite®is widely used in fields ranging from precision machinery to housewares, from automobiles to advanced medical equipment. Panlite® has many notable features such as impact resistance, heat resistance, dimensional stability, electrical properties, transparency and sanitation. Multilon® combines the features of polycarbonate resin (PC) and acrylonitrile-butadiene-styrene (ABS) resin, and is used in a wide range of fields, including electrical/electronics, OA, automobiles, medical care, and lighting. Panlite® has many characteristics such as heat resistance, dimensional stability, impact strength and transparency, making it an ideal choice to meet a variety of demands.

Features

Panlite®

Panlite® is a thermoplastic resin having the following features, and suitable for injection molding, extrusion, blow molding, etc.

Impact strength

Offers the highest impact strength among all plastics, excelling zinc and aluminum die castings in impact strength.

Temperature range

Stable characteristics in wide range of temperatures.

Electrical properties

Stable electrical property in wide range of temperature, suited for an insulating material.

Transparency

Outstanding transparency among all plastics, suitable for optical and sheet applications.

Dimensional stability

Excellent creep characteristics, dimensions remain almost unchanged by moisture, temperatures and duration conditions.

Flame resistance

Outstanding flame resistance, acquired standard UL94 V-0, V-1, V-2, HB, 5VA and 5VB.

Multilon®

- Standard grade

- General purpose

Excellent balance of heat resistance and impact resistance. And it has flowability higher than that of high heat resistance ABS.

Antistatic grade

The polymer itself has antistatic properties and exhibits excellent antistatic performance with a surface resistance value of 1010 to 1011Ω.

The antistatic effect is maintained even after wiping with a cloth or washing with water.

- Flame retardant grade

- Standard type

The standard grades have excellent impact strength, heat resistance, moldability and good hydrolysis resistance. Especially suitable for OA equipment housing.

Mineral filler reinforced type

The grades have well balanced high rigidity and excellent moldability, enabling thin-walled housings for OA equipment.

- Automotive grade

- Standard type

The standard grade series have excellent heat resistance, impact resistance, and weather resistance. It exhibits high impact resistance even at temperatures as low as -30°C. - Glass fiber reinforced type

The grades have excellent heat resistance, high rigidity and moldability, making it a suitable material for structural members.

Application

Products Search

You can search our polycarbonate resin grades by various requirements.

Please select your requirements from search form below.

(You can search by any item.Multiple item selection is an AND search.)

Engineering Service

Characteristics

Design and molding

Download

Related information

Solution

Automotive x Teijin Resin

Teijin meets the needs of the automotive industry with innovative materials and technologies. Our high-performance resins, which enhance lightweighting, durability, and safety, form the foundation of environmentally conscious products and contribute to achieving sustainable mobility.

Medical care & Healthcare x Teijin Resin

Teijin addresses the demands of the healthcare industry through cutting-edge materials and technologies. Our premium resins are utilized in medical devices and pharmaceutical packaging, ensuring safety and reliability. With superior chemical and heat resistance, they maintain stable performance even in highly precise medical settings.

High-Speed Communication x Teijin Resin

Teijin supplies advanced materials for next-generation communication technologies, offering products with superior impact resistance, flame retardancy, thermal conductivity, and low dielectric properties. We develop solutions for generative AI and stable 5G communication, including products that minimize heat generation and endure harsh outdoor conditions.

Case Study

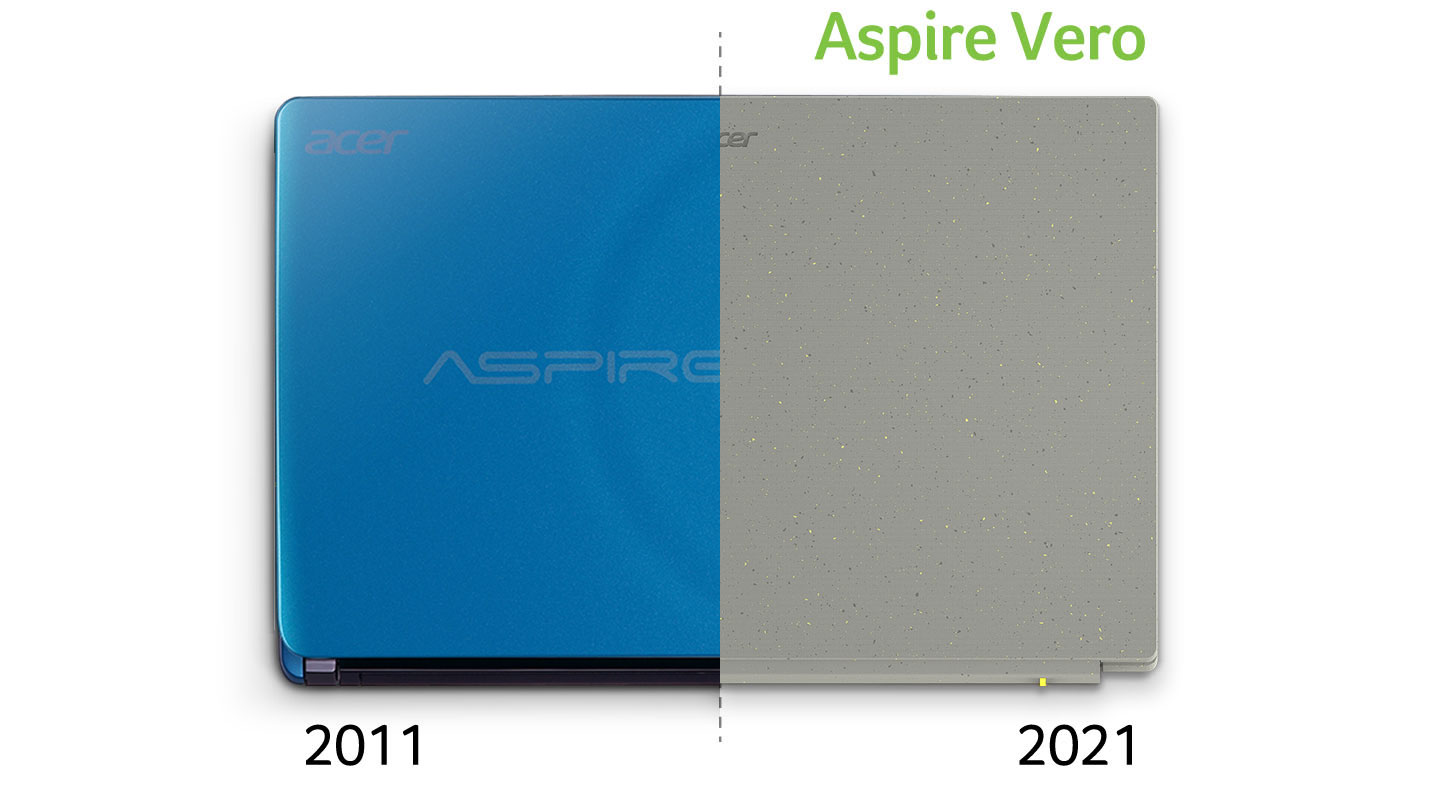

Creating a Laptop PC Housing that is Unpainted, has a High Design, is Environmental Friendly, and has Durability.

Polycarbonate resin with added PCR plastic eliminates problems by the design of foreign particles!

Technology

Polycarbonate resin Panlite® for Scratch-resistant

Teijin's scratch-resistant polycarbonate resin is an excellent material that maintains a beautiful, long-lasting appearance, with transparency, surface hardness surpassing PMMA, impact resistance, and heat resistance.

Polycarbonate resin Panlite® for UV-A transmission with weather resistance (Under development)

Teijin's UV-A transparent weather-resistant polycarbonate is an innovative material that transmits UV-A wavelengths of 330 nm or more while providing excellent weather resistance. It combines ease of processing with high impact resistance, making it suitable for a wide range of applications, including medical equipment and industrial filters.

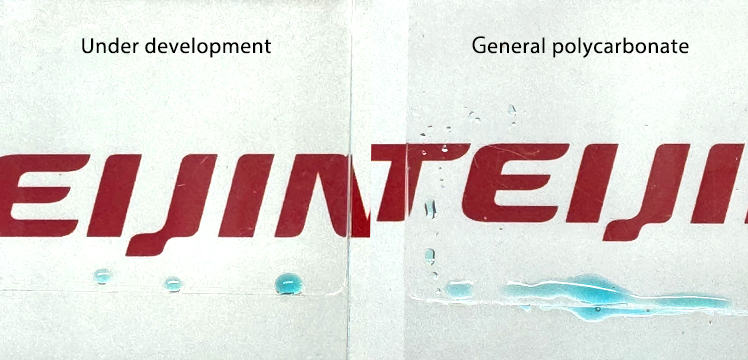

Polycarbonate resin Panlite® for Water-Repellent

Teijin's water-repellent polycarbonate resin maintains the inherent transparency of polycarbonate while retaining its water- repellent and stain-resistant properties for a long period of time.

Polycarbonate resin Panlite® for foam moldability

Teijin provides high-strength, stable products with excellent durability and color stability, using its unique viscosity control technology in polycarbonate resin development and injection foam molding. We cater to our customers' advanced and diverse needs for heat resistance, insulation, weight reduction, low dielectric properties, and more.

Polycarbonate resin Panlite® for metal joining

Teijin has developed a non-crystalline, non-reinforced metal-bondable polycarbonate resin using its resin development technology and Daicel Miraizu Ltd. metal dissimilar material joining technology called "DLAMP®".

Polycarbonate resin Panlite® for LDS

Teijin has developed a low dielectric polycarbonate resin that excels in supporting the Laser Direct Structuring (LDS) method, which is one of the processing techniques for 3D circuitry (Molded Interconnect Devices - MID). This resin offers excellent low dielectric properties, enabling lightweighting, thinning, and greater design flexibility of devices while minimizing transmission losses.